- Resistivity(25°C):10-16MΩ.cm

- Salt rejection 95-99% (with new RO membrane)

- Conductance:<0.1us/cm

- TDS (RO Water): <10ppm

- 2 water outlets: RO water, deionized water

MICRO Deionized Water System

Feature

- Applicable to various water quality, the case is with powder coating.

- The filter element adopts open mold injection technology and inside the machine

- Korean quick-insert filter column is easy to replace and maintain.

- The electrical appliance and waterways are completely separated to avoid circuit failure caused by moisture and water leakage.

- Online water quality monitoring system, immediately measure the output water quality.

- Automatic RO membrane anti-scaling flushing program, automatic stop when tap water break, automatic water breaking when machine stop, storage tank automatically fill water, automatic stopping when water is full.

- NSF certified pipeline has function of upgrading water quality and quantity.

- Equipped with a portable TDS pen, you can test TDS content, conductance, water temperature anytime, anywhere.

- Double electric water intakes, two kinds water quality, ready to use. Pressure online monitoring.

- Open door at front and back, this make filters replacement easy&convenient, the replacement can be easily completed without using any tools. Double water intakes: pure water and deionized water

Application

Preposition unit of ultra pure water system, supply water for biochemical analyzer, electroplating painting, battery charging, chips washing, microbial culture media, chemical&biochemical regent preparation, buffer making, photographic film processing, stability test chamber, meteorological test equipment, hydrogen generator, salt.

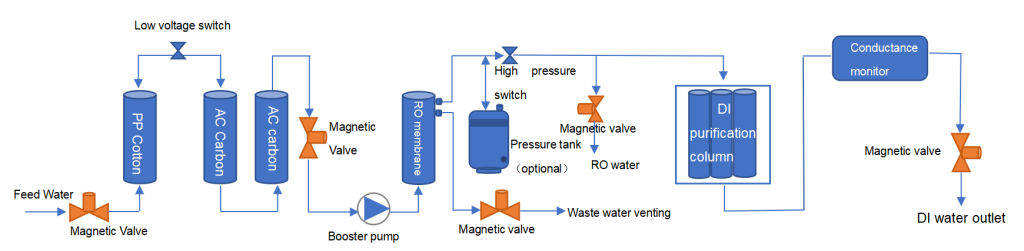

Process

Filter function

- First stage: PP cotton (PPF filter with a pore size of 5 microns): Preliminary filtration of raw water to remove coarser particles, colloids, suspended solids, etc. in the water.

- Second stage: Granular activated carbon: high-efficiency adsorption of odor, color, organic matter, and heavy metals in water.

- Third stage: Compressed activated carbon: further remove residual chlorine, organic compounds, color, odor, turbidity, etc.

- The fourth stage: RO reverse osmosis membrane: 0.0001 micron pore size, effectively removes organic impurities such as viruses and heavy metals in water.

- The fifth stage: Deionization purification column × 3, remove most of the heavy metals and trace elements in the water, and the water quality meets the national laboratory water first-grade water standard.

Specification

| Model | MICRO-DI-10 | MICRO-DI-15 | MICRO-DI-20 | MICRO-DI-30 |

| Output | 10L/H | 15L/H | 20L/H | 30L/H |

| Productin speed | 1.5-2 L/min (with pressure barrel) | |||

| Water requirements | Urban tap water, inlet water pressure: 0.15-0.5mpa, water temperature 5-40℃ | |||

| RO Water Parameter | ||||

| Ion rejection rate | 97%-99% (when using a new RO membrane) | |||

| Organic matter rejection rate | >99% when MW>200 Dalton | |||

| Particle and bacterial rejection | > 99% | |||

| Application | Clean glassware | |||

| DI Water Parameter (ASTM TYPE II Grade Water) | ||||

| Resistivity (25℃) | 10~16 M Ω. Cm @ 25 ℃ | |||

| Heavy metal ion | < 0.1 μS/cm | |||

| Application | Preposition unit of ultra pure water system, supply water for biochemical analyzer, electroplating painting, battery charging, chips washing, microbial culture media, chemical&biochemical regent preparation, buffer making, photographic film processing, stability test chamber, meteorological test equipment, hydrogen generator, salt spray test chamber. | |||

| Electrical requirements | 100-240V, 50/60Hz, 48-72W | |||

| The system configuration | Host machine (including 1 set of purification column) +TDS pen + accessory bag | |||

Consumables

| No | Filter element | Replace Cycle | Remark |

| 2 | 11″ PP cotton filter | About 3-6 month | |

| 3 | 11″ activated carbon filter | About 3-6 month | |

| 4 | 75 GPD RO membrane | About 1-2 years | |

| 5 | 100 GPD RO membrane | About 1-2 years | |

| 6 | 11″ Deionization purification column | About 1000 liter |

Related suggestion

Request for quotation

Product Center

- Laboratory Centrifuge

- Spectrophotometer

- Laboratory Balance

- Water Quality Analysis

- Lab Printer

- Incubator & Oven

- Life Science Instrument

- Autoclave/Sterilizer

- Refrigerator & Freezer

- Microscope

- Regular Desktop Instruments

- Grinders & Mills

- Freeze Dryer

- Organic Element Analysis

- Spectrum/Chromatography

- Water Purification System

- PRP & PRF