- Resistivity(25°C):10-16MΩ.cm

- Salt rejection 95-99% (with new RO membrane)

- Conductivity:<0.1us/cm

- TDS (RO Water): <10ppm

- 2 water outlets: RO water, deionized water

MT Deionized Water System

Feature

- Built-in filter, with 10 micron 316L stainless steel precision filter screen to remove fine impurities instead of PP cotton filter; manual drain valve, automatic cleaning at any time, soft scraping design for more thorough drainage, transparent shell make filtration effect visual.

- The long-acting KDF device adopts the original imported filter material . It removes residual chlorine, heavy metals, and inhibits the growth of fungi at the front of water purification. It has a long service life, better protects the post-purification system, and extends lifetime of ultra-purification column.

- Built-in pressure tank which has inner pouch whose material is anti-bacteria and it is transparent, the inner pouch can be changed anytime.

- ABS engineering plastic case, powder coating technology, with water quality and quantity upgrading function, door is open at the side.

- Type U Korean quick-insert filters, used imported filtering materials.

- Backlight LCD display,dual waterway online monitoring, which can simultaneously display RO conductivity value,DI resistance value and equipment operating status indication.

- Menu-type operation, parameters can be set and modified, operating status display and indication light indicate to promptly reflect machine operating status such as high-pressure shutdown, low-pressure alarm, water full shutdown, etc.

- Alarming for water quality exceeding, automatic filters replacement reminding, water intake time can be set. Take water by touched key, Automatic indication light indicate RO and DI water intake.

- Equipped with a portable test pen, which can test TDS content, conductance and water temperature anytime, anywhere.

- The pipeline adopts a quick-plug interface, the pipe joint passes NSF certification.

- With RS-232C communication interface output, it can be connected with intelligent instruments with RS-232C interface to realize the transmission of measurement data or print records (optional).

- The original imported 3 meters telescopic water taking gun make water collection convenient (optional).

- Can be equipped with ultra-pure water internal circulation system which keep water quality at the highest level(Optional).

Application

Preposition unit of ultra pure water system, supply water for biochemical analyzer, electroplating painting, battery charging, chips washing, microbial culture media, chemical&biochemical regent preparation, buffer making, photographic film processing, stability test chamber, meteorological test equipment, hydrogen generator, salt.

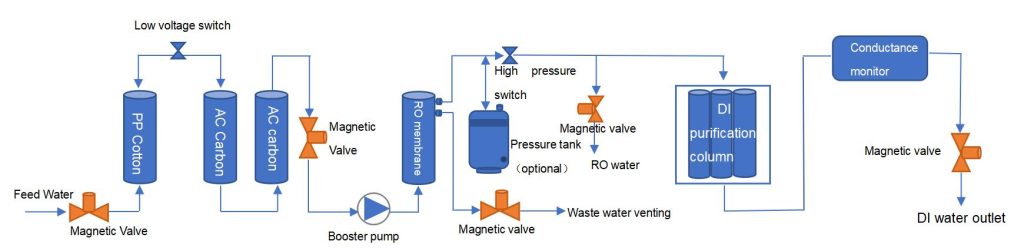

Process

Filter function

- Front filter: 10 micron mesh 316 stainless steel washable filter, remove minor impurities,extend PP cotton lifetime.

- KDF filter: Remove residual chlorine,heavy metals, retrain fungi breed, lifetime is very long, can protect post-positive filters.

- PP: PP cotton filter, remove impurities (greater than 5 micron) such as suspended solid, rust, sludge, colloid, etc.

- AC: Granular activated carbon filter: remove color, odor, residual chlorine and heavy metals

- RO: Reverse osmosis membrane: filter out <1nm pollutants, ions, particles

- DI: deionized-purification column: ion exchange resin bed, H+ and OH– ion removal

Specification

| Model | MT-DI-10 | MT-DI–20 | MT-DI–30 |

| Output | 10L/H | 20L/H | 30L/H |

| Production speed | 1.5-2 L/min (with pressure barrel) | ||

| Water requirements | Urban tap water, inlet water pressure: 0.15-0.5mpa, water temperature 5-40℃,TDS<200ppm | ||

| RO Water Parameter | |||

| Ion rejection rate | 97%-99% (when using a new RO membrane) | ||

| Organic matter rejection rate | >99% when MW>200 Dalton | ||

| Particle and bacterial rejection | > 99% | ||

| Application | Clean glassware | ||

| DI Water Parameter (ASTM TYPE II Grade Water) | |||

| Resistivity (25℃) | 10~16 M Ω. Cm @ 25 ℃ | ||

| Heavy metal ion | < 0.1 μS/cm | ||

| Total organic carbon (TOC) * | <30 ppb | ||

| Application | Preposition unit of ultra pure water system, supply water for biochemical analyzer, electroplating painting, battery charging, chips washing, microbial culture media, chemical&biochemical regent preparation, buffer making, photographic film processing, stability test chamber, meteorological test equipment, hydrogen generator, salt spray test chamber. | ||

| Electrical requirements | 100-240V, 50/60Hz, 48-72W | ||

| The system configuration | Host machine (including 1 set of purification column) + 8L built-in pressure water tank + TDS pen + accessory bag | ||

Consumables

| No | Filter element | Replace Cycle | Remark |

| 1 | KDF composite filter | About 1 year | |

| 2 | 11″ PP cotton filter | About 3-6 month | |

| 3 | 11″ activated carbon filter | About 3-6 month | |

| 4 | 75 GPD RO membrane | About 1-2 years | |

| 5 | 100 GPD RO membrane | About 1-2 years | |

| 6 | 11″ Deionized purification column | About 1000 liter |

Related suggestion

Request for quotation

Product Center

- Laboratory Centrifuge

- Spectrophotometer

- Laboratory Balance

- Water Quality Analysis

- Lab Printer

- Incubator & Oven

- Life Science Instrument

- Autoclave/Sterilizer

- Refrigerator & Freezer

- Microscope

- Regular Desktop Instruments

- Grinders & Mills

- Freeze Dryer

- Organic Element Analysis

- Spectrum/Chromatography

- Water Purification System

- PRP & PRF