- Resistivity(25°C):10-16MΩ.cm

- Salt rejection 95-99% (with new RO membrane)

- Conductivity:<0.1us/cm

- TDS (RO Water): <10ppm

- 2 water outlets: RO water, deionized water

PRO-E Deionized Water System

Feature

- Full-automatic microcomputer control display monitors power supply, water shortage, water production, water full, flush, and strong flush control in real time.

- Fully automatic RO membrane anti-fouling washing program and regular washing program to prolong the service life of RO membrane.

- Real-time online water flow monitoring, water pressure monitoring, water production monitoring, and water pressure monitoring.

- On-line resistivity monitoring of water quality, on-line detection of multiple working states, and real-time operation data.

- The main components are imported brands to ensure excellent water quality and a variety of different configurations to meet your experimental needs.

- Floor-standing design, with movable and fixed feet at the bottom, making installation and movement more convenient.

- The front of the machine is equipped with an independent water intake end, which is convenient and quick.

- Double electric water intake: RO water, ultra-pure water, two kinds of water outlets.

- Multiple safety protection, exquisite chassis and beautiful appearance.

- Free portable TDS water quality testing pen.

- Configure ultra-large capacity purification tank.

Application

Preposition unit of ultra pure water system, supply water for biochemical analyzer, electroplating painting, battery charging, chips washing, microbial culture media, chemical&biochemical regent preparation, buffer making, photographic film processing, stability test chamber, meteorological test equipment, hydrogen generator, salt.

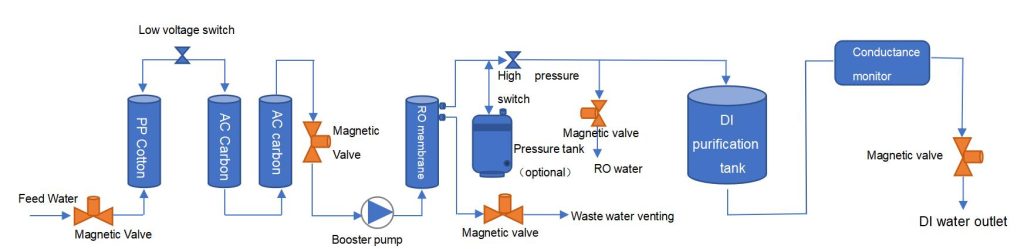

Process

Filter function

- First stage: PP cotton (PPF filter with a pore size of 5 microns): Preliminary filtration of raw water to remove coarser particles, colloids, suspended solids, etc. in the water.

- Second stage: Granular activated carbon: high-efficiency adsorption of odor, color, organic matter, and heavy metals in water Third stage: Compressed activated carbon: further remove residual chlorine, organic compounds, color, odor, turbidity, etc.

- The fourth stage: RO reverse osmosis membrane: 0.0001 micron pore size, effectively removes organic impurities such as viruses and heavy metals in water.

- The fifth stage: Deionization purification tank: remove most of the heavy metals and trace elements in the water, and the water quality meets the national laboratory water first-grade water standard.

Specification

| Model | PRO-E-DI-45 | PRO-E-DI-60 | PRO-E-DI-90 | PRO-E-DI-120 |

| Outut | 45 L/hr | 60 L/hr | 90 L/hr | 120 L/hr |

| Production speed | 1.5-2 L/min(with pressure barrel) | |||

| Water requirements | Urban tap water, inlet water pressure: 0.15-0.5mpa, water temperature 5-40℃,TDS<200ppm | |||

| RO water Parameter | ||||

| Ion rejection rate | 97%-99% (when using a new RO membrane) | |||

| Organic rejection rate | >99% when MW>200 Dalton | |||

| Particle and bacteria rejection rate | > 99% | |||

| Application | Clean glassware | |||

| DI water Parameter(ASTM TYPE II grade water) | ||||

| Resistivity (25℃) | 10-16 M Ω. cm @ 25 ℃ | |||

| Conductivity | <0.1 μS/cm | |||

| Electrical requirements | 110-240V/50-60Hz, 48-72W | |||

| The system configuration | Host machine (including 1 set of purification column)+40 L pressure water storage tank +TDS pen + accessory bag | |||

Consumables

| No | Filter element | Replace cycle | Quantity |

| 1 | 20’’ 5 μm PP cotton | About 4-6 month | 1 pc |

| 2 | 20’’ Refined activated carbon | About 4-6 month | 2 pcs |

| 3 | 400 GPD RO membrane | About 1-2 years | 1 pc |

| 4 | 12L deionization purification tank | About 25 tons | 1 pc |

Related suggestion

Request for quotation

Product Center

- Laboratory Centrifuge

- Spectrophotometer

- Laboratory Balance

- Water Quality Analysis

- Lab Printer

- Incubator & Oven

- Life Science Instrument

- Autoclave/Sterilizer

- Refrigerator & Freezer

- Microscope

- Regular Desktop Instruments

- Grinders & Mills

- Freeze Dryer

- Organic Element Analysis

- Spectrum/Chromatography

- Water Purification System

- PRP & PRF