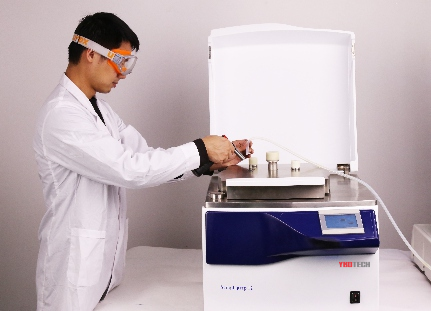

YBOTECH Sampleprep 45 culture media preparation system is a small-scale fully automatic high-temperature and high-pressure rapid sterilization equipment that is suitable for the preparation, sterilization and automated dispensing of culture media in biomedical research sections such as pharmaceutical, food, and medical laboratories.

Two main operation modes for media preparation, plus two extra modes can be selected, and the parameters set to your needs:

- STANDARD mode: For the preparation of standard and highly sensitive culture media. Sterilization temperature/time and dispensing temperature can be set.

- CHOCOLATE AGAR mode: A special two-step program that allows the preparation of complex media. After the first sterilization phase, supplements, e.g. blood, can be added through the adding port. Subsequently, a second heating phase will be performed.

- WATER BATH mode: the culture medium was dissolved at 30-80 °C before formal sterilization. Glassware can be placed in the sterilizer and the liquid in the glassware can be heated in a water bath.

- AUTOCLAVE mode: After the autoclave mode is enabled, it can be used as an ordinary desktop sterilizer to sterilize a small number of test tubes, flasks, and other glassware.

Medium sterilization

Sampleprep ensures the fast and gentle preparation of standard and highly sensitive media. The efficient heating and cooling system combined with uniform stirring minimizes the thermal stress on the culture medium and ensures the nutrition of the culture medium.

High Operational safety

Before the sterilization starts, there will be a program to automatically check the air-tightness of the whole system, for example: whether the sealing ring of the pot cover is intact, which can avoid the pressure relief caused by the sudden air leakage of the medium during the sterilization process, in addition, Sampleprep is equipped with 4 independent temperature/pressure detectors to ensure the high safety of users and working environment. Equipped with an independent over voltage safety protection device, when the electronic detection system fails, the pressure will be automatically released to ensure safety.

Fast Heating

Powerful heating elements permit fast media processing. This minimizes thermal stress and ensures high fertility of your culture media. Pressure and temperature-controlled deaeration guarantees saturated steam in the vessel – an absolute must for complete sterilization.

Reliable Sterilization

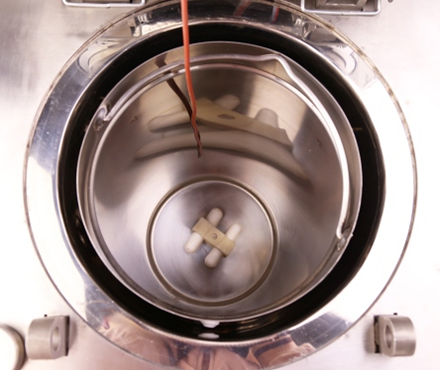

The large and strong magnetic stirrer with adjustable speed and reversing rotation direction ensures homogeneous media preparation over a wide viscosity range. APT-100 temperature probe and microprocessor control of all relevant process parameters allow reliable and complete sterilization of culture media.

Rapid Cooling

Rapid cooling is enabled by an efficient plate heat exchanger. The spatial separation of the cooling water system and the sterilization chamber makes it virtually impossible that culture media will get contaminated by cooling water. The built-in support pressure system prevents a delay in boiling during the rapid cool-down phase and thereby allows an extraordinarily fast and gentle cooling.

Sterilization Data Record

Sampleprep provides tools needed for data recording, including sterilization parameters, working status, etc., to support long-term data storage.

Cleaning and maintenance

The built-in cleaning program can automatically sterilize and clean the cavity, pipes, and valves. High-temperature inter-layer water can be discharged at the end of the program, dissolve and eliminate the residual medium. This sterilizes all the pipes and parts in the whole machine and provides a good environment for the next use.

| Model |

MediumPrep 12 |

MediumPrep 30 | MediumPrep 45 |

MediumPrep 60 |

| Capacity |

12L |

30L | 45L |

60L |

| Chamber size(Ø×H) |

300×260mm |

300×640mm | 400×480mm |

400×685mm |

| Bucket size(Ø×H) |

260×220mm |

260×600mm | 380×440mm |

380×640mm |

| Design temperature |

147°C |

|||

| Sterilization temperature |

70°C-130°C |

90-135℃ |

||

| Dispensing temperature |

25°C-80°C |

35-80℃ |

||

| Water bath temperature |

30°C-80°C |

0-100℃ |

||

| Temperature accuracy |

0.1°C |

0.1°C |

||

| Temperature deviation |

0.5°C |

1°C |

||

| Time Setting Accuracy |

1min |

1min |

||

| Max. allow pressure |

2.5bar |

|||

| Design pressure |

3.5bar |

|||

| Chamber sterilized water |

Deionized water, can automatically enter the water, pressure ≥ 1bar, |

|||

| Circulating water |

Tap water, pressure≥ 1bar |

|||

| Sterilization chamber material |

SS316L |

|||

| Dispenser port |

3 |

2 | 2 |

2 |

| Feeding port |

1 |

1 | 1 |

1 |

| Stirrer speed |

120, 240rpm quick selectable; 0-240rpm stepless adjustable |

|||

| Heating power |

3.6kW |

6.6kW |

15kW |

|

|

Power supply |

220-240V, 50/60 Hz, 20A |

3×380-420V, 50/60Hz, 32A |

3×380-420V, |

|

| Dimensions(W×D×H) |

555×700×550mm |

555×700×980mm | 670×790×920mm |

670×790×1120mm |

| Weight |

85 kg |

122kg | 160kg |

180kg |

Request for quotation

Product Center

- Laboratory Centrifuge

- Spectrophotometer

- Laboratory Balance

- Water Quality Analysis

- Lab Printer

- Incubator & Oven

- Life Science Instrument

- Autoclave/Sterilizer

- Refrigerator & Freezer

- Microscope

- Regular Desktop Instruments

- Grinders & Mills

- Freeze Dryer

- Organic Element Analysis

- Spectrum/Chromatography

- Water Purification System

- PRP & PRF